Well, if you’re ever wanderin’ around them big factories or steel plants, you might hear folks talkin’ about these things called furnace refractory bricks. Now, don’t go thinkin’ they are some kinda fancy newfangled gadget, no sir. These are just tough ol’ bricks, but they’re real special when it comes to standin’ up to heat. I reckon if you’re workin’ with fire or tryin’ to heat somethin’ up real hot, these bricks are what you need. Let me tell you a bit more ’bout ’em so you can understand why they’re so important.

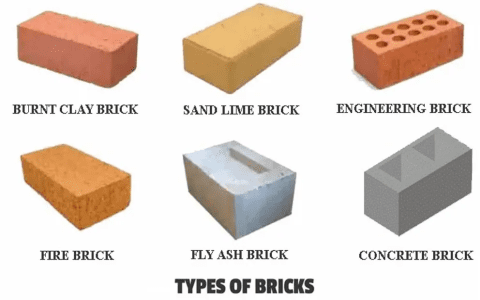

Furnace refractory bricks, also known as firebrick, are basically strong bricks made from materials that can handle all that high heat without breakin’ down. They’re used to line up furnaces, kilns, and fireboxes—basically anyplace where there’s a lot of fire, like in a steel factory or a big oven. The job of these bricks is to protect the walls of the furnace, so they don’t melt or crack under the intense heat. Without ’em, well, everything would burn up or get ruined real quick.

Now, these bricks ain’t made from just any old clay or mud. They’re made from special stuff like bauxite, magnetite, dolomite, and some other fancy materials. Magnesite bricks, for example, are made up of about 85% magnesium oxide and a little iron oxide. These are real good for lining the inside of furnaces ’cause they can take heat without fallin’ apart. Then there’s the dolomite bricks, which can stand temperatures from 1400 to 1600 degrees. So, when you need a furnace that can get super hot, these bricks are your best friend.

But don’t think all furnace bricks are the same. No sir, there’s a whole bunch of ’em! You got your fire clay bricks, which are made mostly from clay and alumina. Then you got high alumina bricks, which are stronger and can handle even higher temperatures. And there’s also silica bricks made from mostly silica, which is real good when you need something to stand up to high heat without fallin’ apart. It’s like pickin’ the right kind of wood to burn, you gotta know which one’s best for the job.

Now, you might wonder why these bricks don’t melt when the furnace is so hot. Well, the secret’s in the materials. Most of ’em are made with minerals that don’t burn or break down easily. Take silicon carbide bricks, for example—they’re made with a high percentage of silicon carbide, which is real strong against heat. Or zirconia bricks, they got some real tough stuff in ’em that can take extreme temperatures without a hitch. Ain’t no surprise these materials are used for stuff that gets hotter than a summer day in the south.

In them big ol’ factories, it’s all about efficiency, ain’t it? The higher the temperature you can manage, the quicker you can get your work done. Refractory bricks help with that, too, because they keep the heat inside the furnace where it belongs. Without ’em, all that heat would escape and you’d be wastin’ energy, which costs a pretty penny these days. And with the way energy prices keep risin’, you want every bit of heat you can get. That’s why these bricks are so crucial for the folks runnin’ them big machines and factories.

And don’t be thinkin’ that just ’cause these bricks are tough, they don’t need no care. Just like how you gotta tend to your stove at home, them big ol’ furnaces need regular maintenance too. Refractory bricks can crack over time, especially if they’re workin’ real hard in a high-temperature furnace. So, it’s important to keep an eye on ’em and replace any that get damaged. Just like you wouldn’t leave your chimney goin’ without a check-up, you don’t wanna leave your furnace linings in bad shape.

All in all, furnace refractory bricks might sound like a small thing, but they’re really mighty important. Without ’em, we wouldn’t be able to make steel, fire bricks for our homes, or even melt metals to make stuff like cars and tools. So, next time you see one of them big ol’ furnaces in a factory, just remember, it’s them bricks inside that’s keepin’ things from blowin’ up! Ain’t that somethin’?

So, if you’re ever in the business of buildin’ or maintainin’ these big ol’ furnaces, you best be sure you know what kind of refractory bricks you need. Trust me, they might just be the unsung heroes of the whole operation. If you pick the right ones, your furnace will last a whole lot longer, and that means less time fixin’ things and more time heatin’ things up! Pretty important, if you ask me.

Tags:[furnace refractory bricks, firebrick, magnesite bricks, dolomite bricks, high alumina bricks, silica bricks, furnace lining, heat-resistant bricks, refractory materials, industrial furnaces, fire management, energy efficiency]