Well, let me tell ya, when it comes to them forge materials, there’s a whole lotta different kinds. Now, back in the day, all we had was simple stuff like steel and iron, but now, there’s all sorts of fancy metals that folks use for forging. Forging, you see, is when they take a big chunk of metal, heat it up, and then pound it or press it into shape. Kinda like how we’d shape clay when we was kids, only a whole lot hotter and heavier!

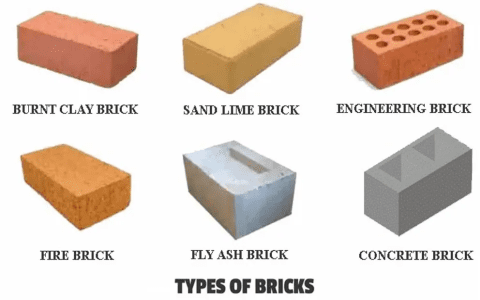

So, the most common materials they use for forging are things like carbon steel, alloy steel, stainless steel, and aluminum alloys. Now, I don’t know much about them fancy alloys, but I do know they make a lotta things like car parts and tools. Aluminum, for example, is used when they need something light but still strong. Things like airplane parts, you know. Then there’s stainless steel, real shiny stuff, good for things like kitchen utensils and, I hear, even medical tools. Them alloys, well, they combine different metals together to make a material that’s stronger or better at handling heat. Ain’t that somethin’?

Now, titanium’s another one they use. I don’t know about you, but I sure wouldn’t want to mess with no titanium unless I had a good reason. It’s tough and light, but real expensive! Used in aerospace and high-end stuff like that. Then there’s copper and brass, they’re a bit softer but still used in some forgin’ jobs, mostly for things like pipes or fancy jewelry. I reckon it’s all about what you’re makin’ and how tough you need it to be.

There’s a lot of ways to do forging, depending on the materials and what kinda shape you’re lookin’ to make. Now, most people use machines like hammers or presses to do the work. You’ve probably seen them big hammers, like the ones they use in blacksmith shops, hittin’ down on that metal. Well, they got them power hammers now, and some presses too. You gotta heat the metal up real good before you hit it, ’cause if it’s too cold, it’ll crack. That’s why you hear folks talkin’ about hot forging, warm forging, and cold forging. It all depends on how hot that metal is when you’re hammerin’ it!

Hot forging, that’s when you heat the metal up real high, almost to the point where it’s glowin’ red or orange. This makes the metal easier to shape, but you gotta be careful—too hot, and it could burn up or crack. Warm forging’s kinda in between, and cold forging, well, that’s when you don’t heat it up at all. You just press it into shape at room temperature, but that’s tougher work for sure!

Now, when you’re choosin’ a material for forgery, you gotta think about what it’s gonna be used for. Some things need to be real tough and can handle a lot of heat, like parts for engines or tools that are gonna get a lotta wear and tear. That’s where them superalloys come in. They’re special materials made to handle extreme temperatures and stress. Them alloys are a mix of metals that have been specially designed to resist wear, corrosion, and heat. High-tech stuff, for sure.

And then, you got the process. Forging can be done a few ways, like open die forging, where the metal’s pressed between two big dies, or closed die forging, where the metal gets squished into a mold that shapes it just right. Open die’s a bit like hammerin’ a nail, while closed die’s more like pouring something into a mold. Each way’s got its own purpose, dependin’ on what you’re makin’.

Materials Used in Forging

- Carbon Steel: Strong, common in tools and machinery.

- Alloy Steel: Stronger than regular steel, used for heavy-duty parts.

- Stainless Steel: Good for corrosion resistance, used in kitchens and medical equipment.

- Aluminum Alloys: Lightweight, used in things like cars and airplanes.

- Nickel Alloys: Tough stuff, used in extreme temperatures, like in gas turbines.

- Brass and Copper: Softer metals used in things like pipes and electrical wiring.

- Titanium: Lightweight, strong, and expensive, used in aerospace and high-performance equipment.

All these materials gotta be chosen with care, ‘cause not every metal works the same in all situations. Some of ‘em can handle a lot of heat, some can’t. Some are tougher than others, but might be harder to work with. And then there’s the price—some materials cost a whole lot more than others. So, when they’re choosin’ a material for forgery, they’ve gotta keep all that in mind.

And I reckon, the bigger the job, the more you gotta pay attention to the details. It’s not just about pickin’ any old material and hittin’ it with a hammer. You need the right material for the job, and then you need the right forge and the right process to make it work. That’s why you see them fancy machines and presses doin’ the work these days, ’cause it ain’t just about whackin’ away at the metal. It’s about makin’ sure it’s shaped right without messin’ it up. Some of these new machines even got controls to change the speed of the hammer, so they can make sure the metal’s gettin’ hit just right!

So, that’s a little bit about forge materials and what goes into it. There’s a lotta different metals out there, and each one’s got its own job to do. It’s a whole science, I reckon, but at the end of the day, it’s about makin’ things tough, durable, and useful. Whether it’s a little part or a big ol’ engine, it all starts with pickin’ the right material and hammerin’ it into shape. Ain’t that somethin’?

Tags:[forging materials, carbon steel, alloy steel, stainless steel, aluminum alloys, titanium, superalloys, forging process, hot forging, cold forging, materials in forging, metallurgy]