Now, if you’re lookin’ to build a forge, one of the first things you gotta think about is that stuff called refractory cement. It’s real important, ’cause you can’t just go slappin’ any ol’ cement around your forge. No sir! You gotta have that special cement, the kind that can handle them high temperatures. Refractory cement’s used to coat the inside of the forge, makin’ sure the heat don’t escape and that your forge lasts a good long while.

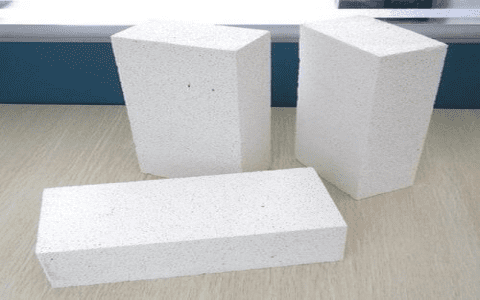

What’s Refractory Cement Made Of? Well, let me tell ya, it’s made up of some mighty tough stuff. They mix things like aluminum oxide and other heat-resistant minerals to make it strong and able to handle them high temps—think over 2000°F! Now, you might hear folks call it “castable” or “refractory concrete,” but it’s all the same thing, just a fancy name for a material that won’t melt under the intense heat of a forge.

Now, when you’re buildin’ a forge, you can’t just use any cement that comes your way. Nope, you need this special kind that won’t crack and crumble when the heat starts comin’ in. It’s gotta be durable, see, and this cement is just the thing. They use it to make fireboxes and other heat-heavy things like kilns and ovens too. It’s built to last, and that’s why it’s so important to get it right.

Why Is It Important? Refractory cement’s the one thing that keeps your forge from fallin’ apart when you start makin’ metal glowin’ hot. If you try usin’ regular cement or somethin’ cheap, you’re askin’ for trouble. The heat will just tear it apart! You need the right stuff that can take the heat and keep your forge runnin’ safe. It’s used to line the firebox inside your forge, keepin’ all that heat where it belongs—inside, heatin’ up whatever metal you’re workin’ with.

Now, a lot of folks like to mix up their own little concoction of clay and refractory cement. It’s a cheaper way to make it, but still gets the job done. You just gotta know the right mixin’ and how thick to lay it on. Don’t go skimpin’ on the layers, though! Too thin, and it won’t hold up. Too thick, and you’ll run outta room inside your forge for the metal.

- Step 1: Start by buildin’ the base of your forge. Make sure it’s sturdy, ‘cause that’s where all the heat’s gonna be.

- Step 2: Coat the inside with a thin layer of refractory cement. Be careful not to go too thick.

- Step 3: Once that’s dried, you might want to add a second layer for extra protection.

- Step 4: After it’s all dried up and good, light up a small fire inside to cure the cement and harden it up.

How to Use Refractory Cement Now, I know you might be wonderin’, “How do I use this stuff, Granny?” Well, it’s not that hard. You just gotta make sure your forge is clean and dry before you put it on. Start with a thin coat, and then let it dry real good. It’ll get hard like a rock, and you can keep adding layers until you feel it’s thick enough to handle the heat.

But don’t think you’re done yet! You gotta make sure the cement is well-cured before you turn that forge up high. The best way to do this is by slowly heating up the forge with a small fire for a couple of hours. This will make sure the cement bonds real nice and tight and gets ready for the big heat.

Final Thoughts If you’re serious about blacksmithin’ or just want a good forge to melt down some metal, you can’t skimp on the refractory cement. It’s the key to keepin’ things safe and workin’ right. Make sure you use the right kind, apply it properly, and let it cure before puttin’ that forge to full use. You won’t regret it, I promise ya that!

Tags:[refractory cement, forge building, blacksmithing, high temperature cement, gas forge, metalworking, heat-resistant material, castable refractory]