Well now, let me tell y’all ‘bout kiln bricks, or what some folks like to call fire bricks, or refractory bricks. They’re them tough little things made outta ceramic material, and lemme tell ya, they can take some heat. I mean, they can handle them high temperatures that come from a good ol’ kiln fire, hotter than a summer day in the fields, if ya ask me.

Now, a kiln, that’s a kind of big oven, real fancy-like, used to fire up all sorts of things, from clay to pottery, to making bricks themselves. And you know, folks been usin’ kilns for centuries. Yep, they’ve been around so long, they even had them in them old days when they was building up cities and such. Back then, they’d take raw clay, stick it in the kiln, and bake it till it turned hard as a rock. And them bricks that come outta them kilns? Well, they’re used to build everything from houses to big ol’ chimneys and whatnot.

See, the deal with kiln bricks is they gotta be made special, real tough. If they weren’t, they’d melt down when the fire gets too hot. So what they do is mix up special materials—fireproof ones—and then bake ‘em real slow. That way, when the fire comes up in the kiln, them bricks don’t crumble or turn to dust. Nah, they just keep on goin’, holdin’ up the heat, and helpin’ the kiln do its job.

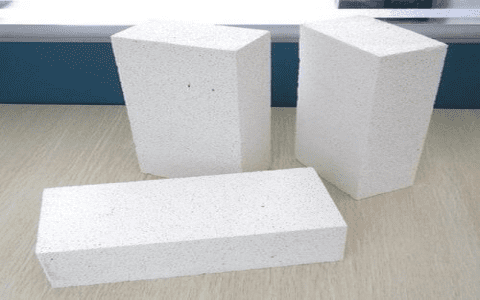

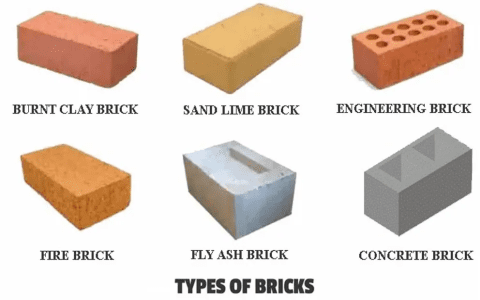

Now, you got two main kinds of kiln bricks out there. There’s the soft ones, they call ‘em Insulating Fire Bricks (IFBs), and they’re real light, kind of like them fluffy biscuits your granny makes, only these ones don’t crumble when you poke ‘em. Then, there’s the hard kind—those are the ones that hold up under all the tough heat. They’re real sturdy, and folks use ‘em in big kilns, like the ones they use to fire up pottery or bake clay bricks for building.

And let me tell ya, makin’ kiln bricks ain’t no easy task. They mix all kinds of materials together—things like clay, silica, and alumina—and fire ‘em up in a furnace. But before they even put ‘em in the furnace, they gotta dry ‘em out good. Can’t have no moisture left in ’em, or they’ll crack when the fire hits. So, it’s a real delicate job. It takes skill to get them bricks just right. They gotta be tough enough to handle all that heat, but light enough to not weigh down the whole kiln.

Different Kinds of Kiln Bricks and Their Uses

- Insulating Fire Bricks (IFBs): These bricks are soft and lightweight. They’re great for kilns that need to hold heat without gettin’ too heavy. They’re often used in smaller kilns or ones that don’t need to go super hot.

- Hard Fire Bricks: These ones are heavier and stronger. They can take them high temperatures, and they’re used in bigger kilns or furnaces that gotta handle serious heat, like them big cement kilns.

- Specialty Fire Bricks: Sometimes, you gotta have bricks that do more than just hold heat. Some folks use special bricks that resist chemicals or even high heat from molten metals. Them’s used in big factories or in them fancy glass-making kilns.

Now, you might be wonderin’ why all this talk ‘bout kiln bricks matters. Well, let me tell ya, without them, we wouldn’t have half the things we got today. A good kiln brick keeps the fire in check and helps make all kinds of things, like pottery, bricks, or even them fancy tiles you see on the floors of rich folks’ houses. Without kiln bricks, that fire would just burn through everything, and we’d be left with nothin’ but ashes.

How Kiln Bricks Are Made

Like I said before, they start with raw materials. They mix up clay, alumina, silica, and some other bits and bobs. Then, they shape ‘em into bricks and let ‘em dry. Once they’re dry enough, they put ‘em in a furnace and bake ‘em at real high temperatures—just like bakin’ bread in a hot oven. This process hardens the bricks and makes ‘em real tough. The higher the temperature they can stand, the better. That’s what makes ‘em refractory—means they won’t melt when things get hot.

And just like makin’ bread, it takes time. You can’t rush it. You gotta be patient. Let them bricks sit in that fire till they get just right, and then they’re good to go. Once they’re done, they’re used in all sorts of kilns, and the cycle continues—buildin’, firein’, and creatin’ all the things we use every day.

Why Are Kiln Bricks So Important?

Well, without kiln bricks, you wouldn’t be able to bake things in the kiln. No baked clay pots, no shiny ceramic dishes, and no fire-resistant furnaces for melting metals. In other words, kiln bricks are the backbone of any high-temperature process. They help the kiln retain heat, keep the temperature steady, and make sure the process goes smoothly. It’s a bit like the foundation of a house—without it, everything would collapse.

So, when you’re lookin’ to get yourself a kiln or even just some kiln bricks, ya gotta make sure you’re gettin’ the right kind. You don’t want no bricks that’ll crumble on ya when the heat gets too hot. And if you’re buildin’ a big ol’ kiln for a factory or something, well, you better go for them hard bricks that can stand up to the toughest heat.

In conclusion, kiln bricks, they’re somethin’ we might not think about every day, but they’re sure important. They hold the fire, make sure it don’t burn out of control, and help us make all sorts of things we need in life. So next time you see a kiln or a brick, just remember—there’s a whole lotta work goes into makin’ sure them bricks are just right!

Tags:[Kiln Bricks, Fire Bricks, Refractory Bricks, High Temperature Bricks, Kiln Construction, Brick Kilns, Fireproof Materials, Ceramic Bricks]