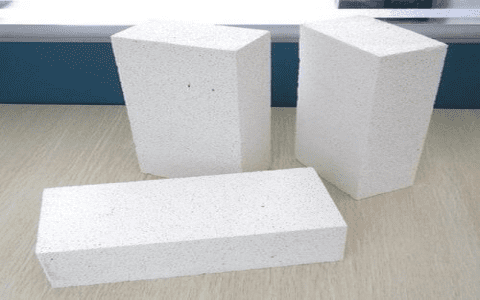

Well now, lemme tell ya somethin’ ‘bout refractory brickwork. These here bricks, they ain’t like them regular bricks you see in normal houses. Oh no, these here are special kinds meant to hold up against some mighty hot temperatures. Folks call ‘em refractory bricks, sometimes they say fire bricks, or even fireclay bricks. Now, these bricks don’t just sit around in a wall, no sir, they’re made for places like furnaces, kilns, fireboxes, and fireplaces – spots where it gets hotter than the sun, ya might say.

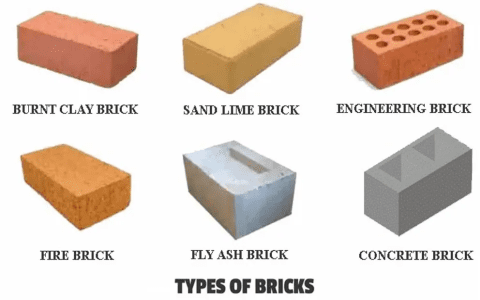

What makes these bricks so tough? Well, that’s the magic, ain’t it? They’re made outta stuff like silicon carbide, alumina, zirconia, or sometimes some kinda mullite – all fancy names, but just think of ‘em as the tough fellas in the brick family. Now, there’s different types of refractory bricks dependin’ on what they’re meant to do. If they’re made of more clay, we call ’em fire bricks. When they’re chock-full of all that alumina and other tough stuff, then they’re proper refractory bricks.

Now, why do folks need such special bricks? I’ll tell ya. See, these bricks don’t just melt away when it gets hot. They hold their own in all sorts of high-heat places, like big ol’ steel factories and cement plants. They’re also real handy in fireplaces to keep things nice and contained. And that’s what makes ‘em perfect for lining furnaces and such – they can take a lickin’ from all that heat and still stay tough.

Let’s talk ‘bout some of the features of these here bricks, alright?

- Heat Resistance: These refractory bricks are made to stand up to all kinds of heat. I’m talkin’ ‘bout temps that could bake a loaf of bread in seconds!

- Low Thermal Conductivity: Now, this means they don’t let the heat just scoot right through ‘em. Keeps things a bit more efficient, ya see.

- Water Absorption: These bricks can absorb 5 to 10% of water. Don’t sound like much, but for a brick, that’s somethin’. It means they won’t crumble easy if they get a bit damp.

- Compressive Strength: They got some serious strength, so they don’t get squashed down like regular ol’ clay bricks.

Where would ya use these refractory bricks? Well, if you’re workin’ on a furnace, you can’t use no regular bricks – those would just turn to dust. Kilns, them hot boxes for firin’ up pottery and ceramics, that’s another big place you’d see refractory bricks. These bricks are used in industrial spots like steel mills, glass factories, cement plants, and even in fireplaces to keep all that heat right where it should be. Without refractory bricks, well, these places wouldn’t last more than a minute or two under all that heat.

And ya know, it takes a skilled mason to lay down these bricks properly. They call ‘em Refractory Masons, folks who know just where and how to set these bricks so they stay strong and don’t shift around. It ain’t just slappin’ a brick down with some mortar – these masons gotta make sure the bricks are laid tight as can be so they work as they should.

So, what’re they made of again? Well, mostly some tough materials like I mentioned – alumina, zirconia, or silicon carbide. But ya also got some fire bricks made from a special kind of clay, and they got a lower amount of alumina and other minerals, so they’re a little softer but still plenty strong.

Now, why don’t we just use these for regular ol’ house walls? Simple answer: cost. These ain’t cheap bricks, no sir. They’re high-quality stuff, specially made, so it wouldn’t make no sense to use ‘em unless you really need to.

In short, if you’re buildin’ somethin’ that needs to hold up to crazy heat, you’re gonna want these here refractory bricks. They’re made to last and keep things safe even when the temps go sky high. So, if ya ever see one of these places – like a steel mill or a big furnace room – just know that underneath all that fire and heat, there’s these tough bricks keepin’ it all together.

Tags:[refractory brickwork, refractory bricks, fire bricks, kiln bricks, furnace lining, high temperature bricks, refractory mason]