Okay, so I’ve been messing around with kilns lately, and let me tell you, it’s been a real learning curve. I decided to make my own bricks for a kiln. Let’s just say it’s been an adventure.

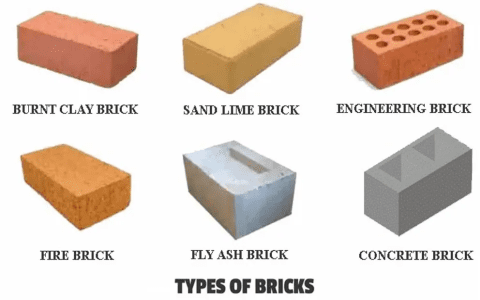

I started by researching what kind of bricks are needed. Turns out, there are these things called “fire bricks.” I just wanted to make something that wouldn’t explode when things got hot. They are for making kilns, which are like big ovens, kind of. You use them to make pottery, or melt metals.

I started looking for what I could use. Apparently, regular bricks are used for building the outside of houses, but they can’t take the high temperature. And I found out that they got different types of bricks for different kilns. For example, glass kilns might need different bricks than pottery kilns.

I heard from someone that some kilns use gas, like natural gas or propane. Those are the things that you cook with. I thought “Hey, I’m not messing with gas. I’ll stick to electric.” Electric kilns are said to be easier to use, especially for beginners. And they’re good for the kind of work I’m doing. I just want to use the kiln for some low to mid-fire work.

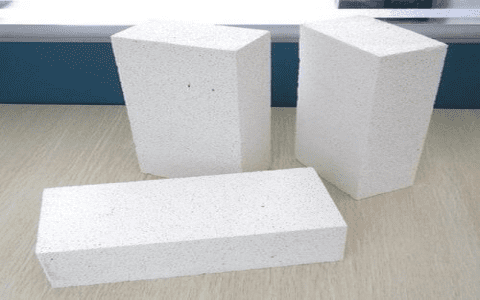

The real tough part was deciding on the material. I needed something that could handle the heat, the abrasion. These “dense bricks” I’ve been hearing about seemed like the way to go. They are good for when things get really hot and there’s a lot of wear and tear inside.

Making the bricks, well, that was a whole other story. My grandpappy used to make bricks, he always said, “low and slow.” So I tried to follow his advice. I mixed the clay and some other stuff and poured the goop into molds. I figured I’d let them bake in the sun for a few days.

- First, I mixed my clay and other materials. I wanted to make sure the consistency was just right.

- Then, I put the mix into my homemade molds.

- I let them dry out in the sun.

It took forever, but finally, I had my bricks! They weren’t perfect, some were a bit uneven, but they were mine. I tried to make them even, but some were bigger than others.

Building the Kiln

Building the kiln was a test of patience. I started stacking the bricks, trying to make a decent structure. I used these special insulating fire bricks to build the walls. After a few tries, I finally had something that resembled a kiln.

I fired it up and waited. The first few attempts were… well, let’s just say I learned a lot. It took some time, but eventually, I got the hang of it. It’s not perfect, but it works!

It’s been a heck of a journey, but I’m proud of my little kiln. It’s a testament to good old-fashioned elbow grease and a bit of “low and slow” wisdom from grandpappy.