Well, now you want to make your own refractory bricks, huh? Ain’t that something! You know, back in my day, we didn’t have all these fancy store-bought things. We had to figure out ways to make do with what we got. If you’re lookin’ to make fire bricks, I’ll tell ya what, it ain’t all that hard, just a little time and patience, and you’ll be makin’ bricks like a pro. Now, don’t go expectin’ it to be perfect the first time, but with a bit of practice, you’ll get the hang of it.

What You Need to Make Refractory Bricks

First thing you gotta know is what you need. Now, most people go straight to the store for stuff like clay or special firebrick material, but you can make do with what’s around the house. I’m tellin’ ya, you don’t need to break the bank. Here’s a little list of what you’ll need:

- Perlite – That’s a lightweight volcanic rock stuff. Ain’t too hard to get, and it holds up well when the heat’s on.

- Sand – Regular ol’ sand, from the beach or wherever you can get it. It’ll help make the brick strong.

- Sodium silicate – Now, this stuff is like a high-temperature glue. You can make it with a mix of drain cleaner and kitty litter. Don’t worry, it’s safe when you mix it right, and it’ll help hold everything together. Just make sure you follow the instructions right, or it won’t work!

- Cement – White cement works best, and you can find it pretty easy. Don’t use regular cement, though, it’s not made to take the heat like the white kind.

- Water – Can’t forget the water. You need to mix everything together just right.

Steps to Make Your Refractory Bricks

Now, let’s get to work. First, you mix your perlite, sand, and cement. About 356 grams of perlite, 1167 grams of sand, and 699 grams of white cement. That’s the basic mix. You can always adjust depending on how much you wanna make. Just make sure you get the proportions right so your brick’s strong enough.

Once that’s all mixed up, it’s time for the tricky part – adding the sodium silicate. You’ll need to add just enough to make the mix into a thick paste. Don’t add too much, though, or it’ll be too runny and won’t hold. Now, the sodium silicate is what makes the brick able to stand up to the heat. It’s like a glue that keeps everything together when things get hot and fiery.

Next, you’ll need to pack that paste into a mold. If you don’t have a brick mold, don’t worry. You can use just about any container that’ll hold its shape when it’s full. Just make sure it’s sturdy enough, because that’s what’ll shape your bricks. Fill the mold up with your mix and pack it in nice and tight. You don’t want any air bubbles inside, so give it a little tap on the sides to get everything settled.

Once it’s all packed in, cover it up with some plastic to keep it moist. You can leave it for about 24 hours, maybe a bit more, depending on the weather. Let it harden up, but not too quick. You don’t want it to crack.

Drying and Curing Your Bricks

Now, after you let it sit and dry out, it’s time for the curing. You can’t just use it right away after it’s dried. No, no. You gotta cure it to get that real heat-resistant quality. Slowly bake it in a low-temperature oven, work your way up to about 500°F (that’s about 260°C for you folks who like the Celsius scale). It’ll take a few hours to get it to that point, so be patient.

You can use a regular oven, or if you’ve got a kiln or something like that, it’ll work even better. Just make sure you don’t rush it. It’s all about slow and steady.

Using Your Refractory Bricks

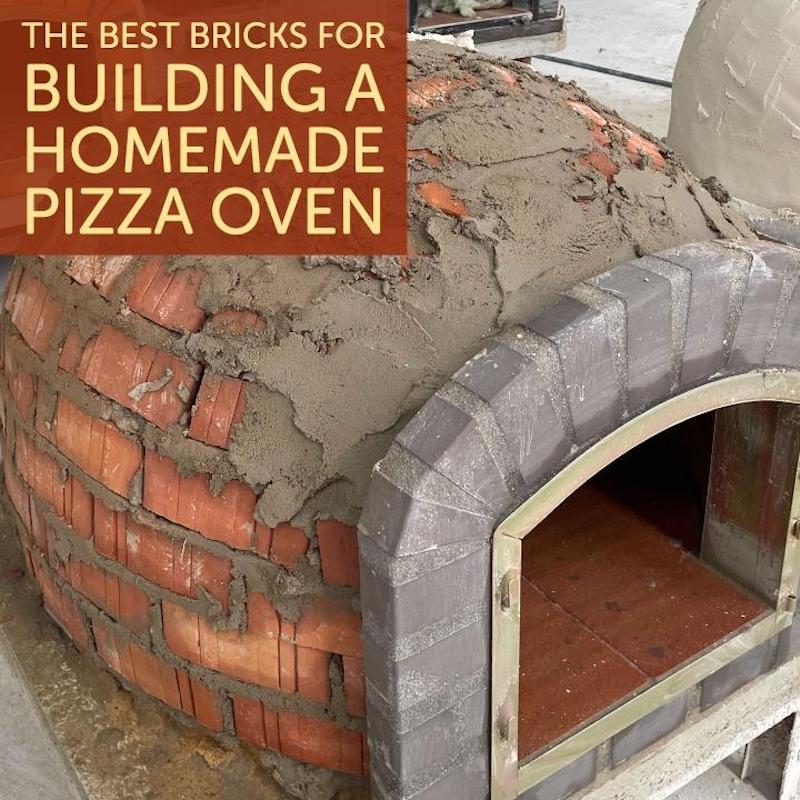

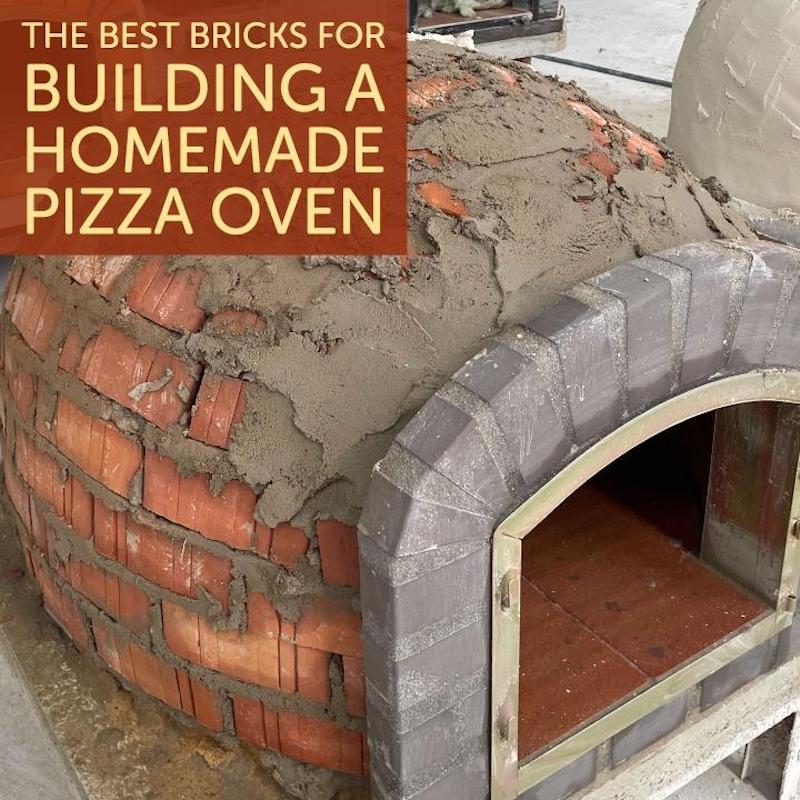

Once your bricks are all done and cured, you can use ‘em for whatever you need! They’re great for making kilns, pizza ovens, fire pits, and even chimneys. They hold up to high temperatures, so don’t worry about them cracking under the heat. Just make sure you lay them out with refractory mortar. Don’t use regular mortar, no sir! It won’t hold up in the heat like the real stuff. And make sure your joints aren’t too big – about an eighth of an inch is good.

You can use ‘em inside or outside, but just remember – if they’re gonna be outside, make sure they’re protected from the rain. You don’t want ‘em getting all soggy and falling apart.

Tips and Tricks

I’ve made a fair number of these things, so let me give you a few tips:

- If you want a lighter brick, try mixing in some clay or ceramic fiber. It’ll make ‘em easier to handle and still heat-resistant.

- Always make sure you’re mixing in the right amounts. Too much of one thing or not enough of another, and your brick won’t hold up to the heat.

- Be patient with the curing process. If you rush it, the brick could crack when it’s exposed to heat.

Making your own refractory bricks is a fine way to save money and get exactly what you need for your project. It’s simple, but you gotta pay attention to the details. Stick with it, and you’ll have bricks that’ll last you for years. Now, go ahead, get your hands dirty, and start makin’ those bricks!

Tags:[DIY Refractory Brick, Firebrick, High Temperature Bricks, Making Firebricks, Refractory Cement, Kiln Bricks, How to Make Firebricks]