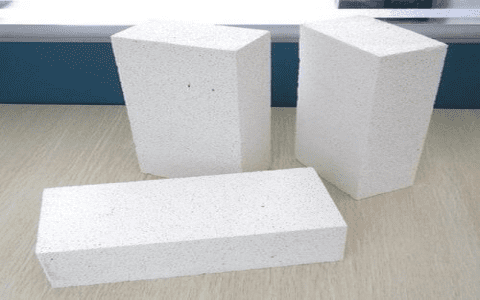

Alright, let’s talk about them furnace refractory bricks, you know, the ones they use in them real hot places. I ain’t no fancy engineer or nothin’, but I know a thing or two ‘bout what works and what don’t. See, these bricks, they ain’t your regular house bricks. They gotta be tough, real tough, to stand up to all that heat.

Now, they got different kinds, you see. Some folks call ‘em basic refractory bricks. Sounds fancy, huh? But it just means they’re made of stuff like bauxite, magnetite, and dolomite. I heard tell that magnesite bricks are good for lining furnaces ‘cause they got this magnesium oxide stuff in ‘em, and a little bit of iron too. Makes ‘em strong, I reckon. And them dolomite ones? They can take even more heat, like, hotter than your oven ever gets, way hotter.

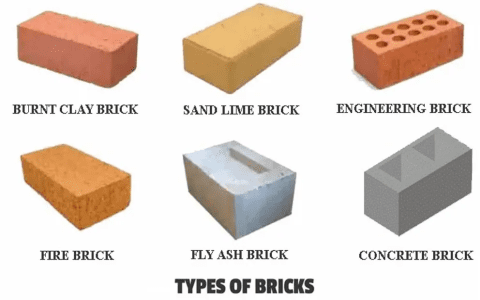

Then there’s the composition, that’s what they’re made of. Some are made of silicon carbide, sounds like somethin’ from outer space, don’t it? But it’s tough stuff, real tough. They also use alumina and zirconia, more fancy words, but it just means they can handle the heat. Some bricks, they call ‘em fire bricks, they got more clay in ‘em, not as much of that fancy stuff. Still good, mind you, just different.

I remember seein’ ‘em make bricks once. They put ‘em in these big ol’ ovens, called kilns, and bake ‘em good. Real hot, like I said. Gotta get all the water out and make ‘em strong. Some kilns are long tunnels, some are just big batches. Either way, it takes a while to get them bricks just right. Can’t rush it, you know.

- Types of Refractory Bricks: Basic refractory bricks (bauxite, magnetite, dolomite), magnesite bricks, dolomite bricks, SiC refractory bricks, fire bricks.

- Material Composition: Silicon carbide, alumina, zirconia, mullite, clay minerals.

- Manufacturing Process: Firing in tunnel or batch kilns.

Now, why do they use these special bricks anyways? Well, it’s simple. They gotta keep the heat in, see? If you used regular bricks, they’d just crumble and fall apart. These refractory bricks, they’re like a good thick coat on a cold day. They keep the heat where it’s supposed to be, and they don’t melt or crack under pressure. And they are a decent insulator, which means they keep the heat from escaping, saves money on fuel I suppose.

Think of it like bakin’ a pie. You need a good pan, right? One that won’t warp or burn in the oven. Well, a furnace is like a giant oven, and these refractory bricks are like the best pie pan you ever did see. They gotta hold up to all that heat and keep everything inside cookin’ just right. If them bricks ain’t good, the whole thing goes to pot.

And it ain’t just furnaces, you know. They use these bricks in all sorts of places where it’s hot. Like, them big metal ladles they pour the hot metal from. Or them chimneys at the factories, the ones that let out all that smoke. Them places are hot, real hot, and you need bricks that can take it.

So, there you have it. A little bit about furnace refractory bricks. They ain’t pretty, but they’re important. They keep things runnin’ smooth and safe, and that’s more important than lookin’ fancy, if you ask me. Just good, strong bricks, doin’ their job, day in and day out. And that’s all there is to it, really.

I tell you, it is all about common sense, something young people do not have these days. They should learn from old folks like me.

Tags: [refractory bricks, furnace bricks, high-temperature bricks, magnesite bricks, dolomite bricks, fire bricks, kiln, insulation, heat resistance, materials science]