Well, now, if you’re wondering about ceramic density, you’ve come to the right place. I’ll tell you what I know in the simplest way possible, so even my old neighbor down the road can understand! Ceramic, you see, is one of them things that folks use for all sorts of stuff. It’s in pots, tiles, electrical stuff, and even some fancy materials in industries. But one thing that’s real important when we talk about ceramics is their density.

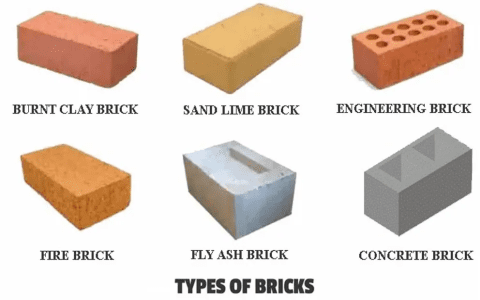

Now, what do we mean by “density”? Simple – it’s how heavy a material is for its size. In the case of ceramic, it’s how packed the particles are inside it. You might think of it like a jar of beans. If you squish them all in tight, it’s real heavy. But if you leave gaps between them, it’s lighter. Same thing with ceramic – if the particles are packed tight, it’s denser, and if not, it’s less dense. Now, ceramic density can vary depending on what kind of ceramic it is. You’ve got some types that are denser than others. Let me tell you about that.

Different kinds of ceramic, like alumina and zirconia, have different densities. Alumina, for instance, is a common one and it’s got a density around 3.9 to 4.2 grams per cubic centimeter. That’s heavier than water, but not too heavy when you compare it to other materials. On the other hand, zirconia is a little denser, usually around 5.6 grams per cubic centimeter. So, you can see that depending on the type of ceramic you’re dealing with, it can be heavier or lighter.

Now, why do we care about this density thing? Well, it all comes down to what you need the ceramic for. If you’re using it in something like a pot for cooking, you might not care too much about how dense it is. But if you’re making parts for machines or fancy electronic gadgets, well, then the density matters. More dense ceramics can be stronger and more durable, which is important if you’re dealing with high temperatures or need something that’s gonna last a long time without breaking.

There’s also something else called fracture toughness. That’s how well the ceramic can take a hit without cracking. Denser ceramics tend to have better fracture toughness. Take zirconia, for example. It’s not just dense; it’s tough too. That’s why it’s used in things like dental crowns or other parts that need to hold up under pressure. Alumina, while not as tough as zirconia, is still pretty good for a lot of uses, especially where strength and resistance to wear and tear are important.

But hold on a minute! Not all ceramics are the same when it comes to how dense they are. Some might have densities as low as 2.5 grams per cubic centimeter, while others might go all the way up to 6 grams per cubic centimeter. It really depends on how they’re made and what they’re meant for. Advanced ceramics, those fancy ones used in high-tech stuff, usually have that higher density range. And like I said, this affects everything from strength to how well they handle heat, so it’s a big deal.

Density and Forming Methods

How they make the ceramic also has something to do with its density. You can’t just toss some clay and minerals in a mold and expect the same result each time. Different methods of forming ceramic materials can change how packed the particles are, which in turn affects the density. If you fire them in a high-temperature oven, you get a denser, stronger material. If you don’t fire them as long, or if you make them using a different process, you might end up with something less dense, but maybe cheaper and lighter.

So, to sum it all up, ceramic density is important because it affects how strong, durable, and heat-resistant the material is. You’ve got a range of densities, from lighter ones around 2.5 g/cm³, up to heavier ones that go all the way to 6 g/cm³. It all depends on the kind of ceramic you’re dealing with and what it’s meant to do. Whether it’s for a pot or a piece of fancy tech, the density will make a difference in how it performs. Now you know a little more about it, don’t you?

- Alumina: Density around 3.9 to 4.2 g/cm³

- Zirconia: Density around 5.6 g/cm³

- Advanced Ceramics: Density range from 2.5 to 6 g/cm³

- Density affects strength, durability, and heat resistance

So next time you come across a ceramic material, you’ll know that density’s got a lot to do with how well it works. Whether you’re baking a cake in a ceramic pan or using one in a machine part, that density is key to how well it’ll hold up!

Tags:[Ceramic Density, Alumina, Zirconia, Ceramic Properties, Fracture Toughness, Advanced Ceramics, Material Strength, Density in Ceramics]