Well now, if y’all are lookin’ to build yerself a forge or maybe just fix up one of them fancy kilns or fireboxes, ya gotta know about this stuff called refractory cement. It’s a special kind of cement that’s mighty heat-resistant, designed just for places that get hotter than a firecracker on the 4th of July. I reckon it’s a good idea to get the right stuff, ’cause regular cement just ain’t gonna hold up when it’s exposed to all that heat.

What is Refractory Cement?

Refractory cement, ya see, is a heat-resistant material that’s used to line fireboxes, forges, ovens, kilns, and all sorts of other high-temperature equipment. It can handle temperatures that go up to 3,000°F, and that’s hotter than a boiling kettle on a cold winter mornin’! So, if yer planning to make yourself a forge or do some serious work with fire, you best be usin’ this kind of cement.

Now, let me tell ya, regular cement ain’t up to the task. You can’t just take any old cement and slap it on yer forge and expect it to last. The regular stuff might crack or break down when the heat gets too much. But refractory cement? That’s a whole different story! It’s made to withstand all that heat without crackin’ or fallin’ apart.

What’s the Difference Between Refractory Cement and Regular Cement?

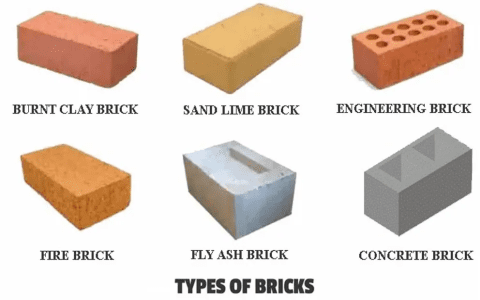

Well, the biggest difference is that regular cement ain’t made for heat. When you put it in a hot spot, like around a fire, it starts to break down and crumble. But refractory cement, it’s made with special materials that resist heat. It holds up real good even in the highest heat, like what you’d find in a forge or a furnace. You can use it to stick bricks and tiles together inside yer firebox, but don’t be thinkin’ you can use it for direct flame contact – it just ain’t meant for that.

Refractory cement is used in a thin layer to hold bricks or tiles in place inside furnaces, kilns, and other high-temperature equipment. It’s mostly for lining the inside of them things, where it ain’t directly exposed to the flames but still needs to handle a lot of heat.

How to Use Refractory Cement for a Forge

Now, if you’re fixin’ to build a forge, ya gotta use this cement right if you want it to last. The first thing to know is you need to apply it in thin layers. You ain’t gonna be buildin’ a thick wall out of it like regular brick mortar. You use this cement to coat the inside of yer forge and stick bricks or fireproof tiles together. Just make sure to get a nice even coat, and don’t go too thick.

One thing to keep in mind is that refractory cement ain’t made for contact with direct flames. So don’t go thinkin’ you can pour it on the bottom of yer forge and expect it to withstand the fire directly. Nah, it’s there to protect the bricks and other parts that are bein’ exposed to heat, but ya need to be careful where ya place it.

Some folks even use ceramic materials as a cheap alternative to refractory cement. You can mold it outta clay and let it dry, then use it to line parts of the forge. Now, it might not be as durable as the real thing, but it’ll hold up for a good while if yer just doin’ some basic forge work.

Other Uses for Refractory Cement

Besides just forges, this cement can be used in all sorts of other high-heat areas, like in crematoriums, incinerators, and even wood stoves. Anywhere there’s gonna be some high temps for long periods, you’ll find folks usin’ refractory cement to make sure things don’t get all cracked up or damaged. It’s a real handy thing to have around when you’re workin’ with heat that would melt regular cement right down to nothin’.

Where to Buy Refractory Cement?

Well now, if you’re lookin’ to get yourself some refractory cement, you can usually find it at any good hardware store, especially the ones that sell stuff for fireplaces, wood stoves, and kilns. If not, you can always look online. Just make sure you’re gettin’ the real stuff – there’s a lot of fake stuff out there that won’t stand up to the heat like it should. Make sure it’s rated for high temperatures, ‘round 2,000°F to 3,000°F, to be safe.

Final Thoughts

So, if you’re buildin’ or repairin’ a forge, kiln, or firebox, make sure you use that refractory cement. It’s the best way to ensure that your high-temperature equipment stays strong and holds up to the heat. Regular cement just won’t do the job, and you’ll be stuck replacin’ things more often than you’d like. Stick with the good stuff, and you’ll be able to forge away to your heart’s content, without worryin’ about cracks or damage from all that fire!

Tags:[refractory cement, forge, high-temperature materials, heat-resistant cement, kiln, firebox, refractory concrete, heat-resistant mortar, ceramic forge materials]